All About Mhs - Material Handling Supply Inc.

All About Mhs - Material Handling Supply Inc.

Blog Article

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

Table of ContentsThe Single Strategy To Use For Mhs - Material Handling Supply Inc.Some Known Details About Mhs - Material Handling Supply Inc. Mhs - Material Handling Supply Inc. Things To Know Before You Get ThisThe 3-Minute Rule for Mhs - Material Handling Supply Inc.Some Known Details About Mhs - Material Handling Supply Inc. Top Guidelines Of Mhs - Material Handling Supply Inc.

This line is called the line of activity. forklift dealer watkinsville, ga. If all-time low of this line goes beyond the security triangular since a lots is too heavy or too expensive, or since the forklift is not on a level surface area it will certainly tip over. A vertical line extending from the center of gravity of the vehicle-load combination must stay inside the security triangle to avoid the forklift from tippingThe other concept to comprehend is the forklifts center of gravity. When unloaded, the forklifts facility of gravity is right regarding right here.

Larger tons shift the center of mass onward even further. Raising the lots also changes the center of mass forward. In order to stop the lift from tipping, the mixed center of gravity of the tons and the lift need to remain inside the stability triangle (at ground degree) whatsoever times.

The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is Talking About

If you have a balanced lots, the lots is not likely to impact the side-to-side center of mass. https://experiment.com/users/mhsinc30677. If you drive on a sloped surface, your facility of gravity could pass outside of the stability triangular and the lift can tip. Every forklift has an identification plate that notes important details concerning the vehicle

To ensure that the center of mass of your forklift stays inside the stability triangular, do not try to lift anything much heavier than the recognition plate permits. Despite exactly how hectic you are, you should inspect your forklift before using it. If you do discover something that could affect the safety and security of the car you must report it quickly.

Adhere to the operators handbooks provided by the tools maker. These handbooks describe the safe procedure and upkeep of forklifts. Keep in mind, the operator is accountable for the safe operation of the forklift. Do a pre-operation inspection before every shift. If the forklift is made use of all the time, evaluate it either prior to each shift or after each change.

The Greatest Guide To Mhs - Material Handling Supply Inc.

It is completed in 2 components: the walk-around assessment, and, the seated examination. OSHA does not require paperwork of a daily examination. Yet it's a good idea to have a list to make certain you don't miss out on any actions. These lists can also be saved as a component of the maintenance document.

Examine the problem of the tires. If the forklift is an outdoor forklift with pneumatic tires, check the air stress and look for extreme wear on the tires. A tire with low air pressure might create the lift to tip when a load is raised. So could a tire failing.

The Definitive Guide for Mhs - Material Handling Supply Inc.

Inspect the engine for any indications of wear, loose links, or leakages. Look for splits or defects in the forks, back-rest, mast, and overhanging guard. Inspect the recognition plate to make sure it is undamaged and understandable.

Beginning the engine. Constantly begin the engine while seated in the operator's positionnever while standing alongside the forklift. Inspect all assesses and warning lights, and the battery or fuel degree. Get accustomed to the controls. Lift and lower the forks, and tilt the mast. Make certain that whatever works efficiently and is clearly identified.

The Best Guide To Mhs - Material Handling Supply Inc.

Examine the brakes by dispiriting the brake pedal. Check the steering. Relocate the click resources forklift onward a few feet.

Leaks might show a hydraulic trouble, and liquids left on the floor are a slipping risk. Look for stimulates or flames coming out of the exhaust system. Pay attention for any unusual noises. If you discover anything incorrect with the forklift throughout the walk-around or seated examination, do not operate it till it has actually been repaired.

The Best Strategy To Use For Mhs - Material Handling Supply Inc.

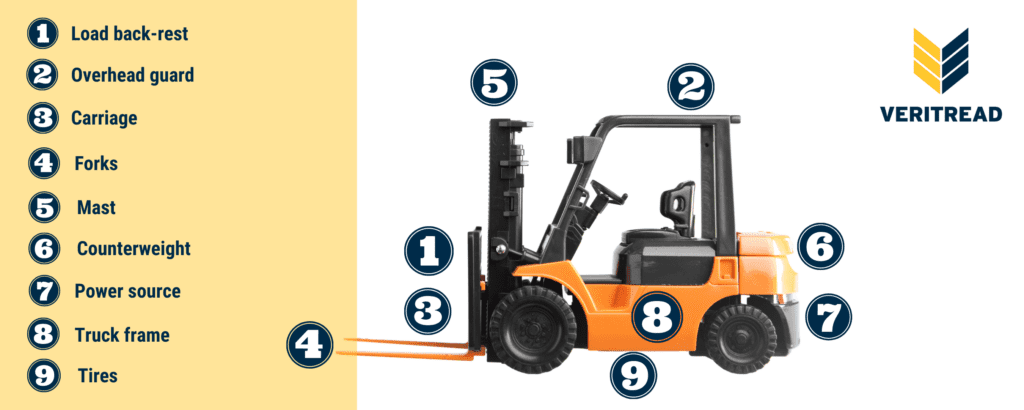

Forklifts have numerous moving components and items that permit the forklift to operate correctly. Comprehending the terminology of the components and makeup of a forklift is essential for effective interaction with others while on duty - https://moz.com/community/q/user/mhsinc30677. Right here are several of the fundamental features and components that compose the makeup of a forklift vehicle

For many forklifts, the mast is designed toward the front of a forklift and directly in the forklift operator's line of vision. Forklift masts come with various sections that elevate or lower the forklift carriage along with the forks.

Report this page